- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

MZEP02

Manzawa

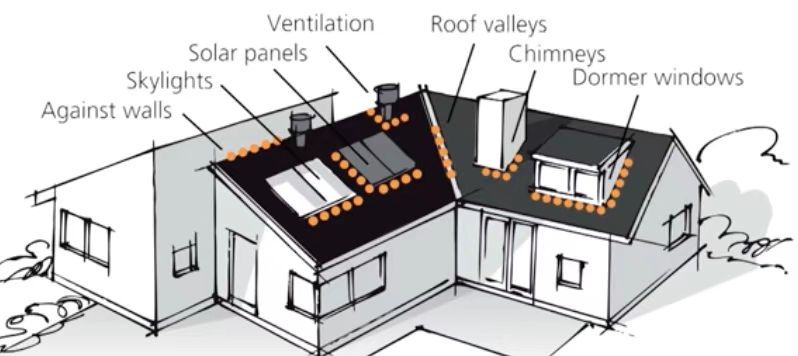

Excellent anti-aging properties, and the service life can be up to 50 years.

High elongation, high tensile strength and small change of heat treatment size;

It has good resistance to plant root penetration and can be made into a waterproof layer of planting roof;Good perforation resistance;

The special modified molecular structure effectively solves the problems existing in the bonding of EPDM adhesive;

Good flexibility at low temperature and good adaptability to environmental temperature changes;

The construction is convenient, the lap joint is firm and reliable, and there is no environmental pollution;

Chemical corrosion resistance, can be used in special occasions; Convenient maintenance and low cost;

Easy to handle details;

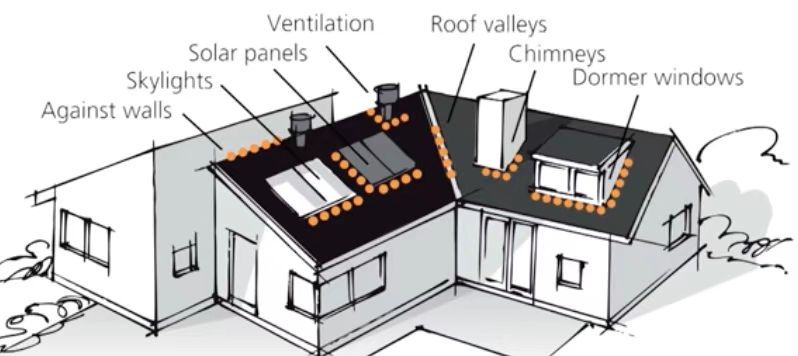

Excellent anti-aging properties, and the service life can be up to 50 years.

High elongation, high tensile strength and small change of heat treatment size;

It has good resistance to plant root penetration and can be made into a waterproof layer of planting roof;Good perforation resistance;

The special modified molecular structure effectively solves the problems existing in the bonding of EPDM adhesive;

Good flexibility at low temperature and good adaptability to environmental temperature changes;

The construction is convenient, the lap joint is firm and reliable, and there is no environmental pollution;

Chemical corrosion resistance, can be used in special occasions; Convenient maintenance and low cost;

Easy to handle details;

Compliance with GB/T 18173.1-2012

| NO. | ITEM | Index | ||

| 1 | ML1 | MF1 | ||

| 2 | Tensile Strength (Mpa) | Room Temperature | ≥7.5 | ≥4 |

| 60℃ | ≥2.3 | ≥0.8 | ||

| 3 | Elongation at Break (%) | Room Temperature | ≥450 | ≥400 |

| -20℃ | ≥200 | ≥200 | ||

| 4 | Tear Strength (kN/m) | ≥25 | ≥18 | |

| 5 | Water Tightness 30 minutes no leakage | 0.3Mpa | 0.3Mpa | |

| 6 | Low Temperature Bending | -40℃ | -30℃ | |

| 7 | Heating Shrinkag | Extend | ≤2 | ≤2 |

| Shrink | ≤4 | ≤4 | ||

| 8 | Hot Air Aging (80℃*168H) | Tensile Strength Retention At Fracture(%) | ≥80 | ≥90 |

| Elongation At Break Retention Rate (%) | ≥70 | ≥70 | ||

| 9 | Alkali Resistance {Saturated Ca(OH)₂ Solution * 168H At Room Temp.} | Tensile Strength Retention At Fracture(%) | ≥80 | ≥80 |

| Elongation At Break Retention Rate (%) | ≥80 | ≥90 | ||

| 10 | Ozone Aging (40℃*168H) | Elongation 40% 500ppm | No Crack | No Crack |

| 11 | Artificial Weathering Aging | Tensile Strength Retention At Fracture(%) | ≥80 | ≥70 |

| Elongation At Break Retention Rate (%) | ≥70 | ≥70 | ||

| 12 | Bonding Peel Strength (shhet and sheet) | N/mm | ≥1.5 | ≥1.5 |

| Retention Rate of Flooding (168H At Room Temp.) | ≥70% | ≥70% | ||

Remark:

Width of ML1 = 1.2m,20m/roll,30kg/roll;

Width of MF1 = 2.0m,20m/roll,50kg/roll

Compliance with GB/T 18173.1-2012

| NO. | ITEM | Index | ||

| 1 | ML1 | MF1 | ||

| 2 | Tensile Strength (Mpa) | Room Temperature | ≥7.5 | ≥4 |

| 60℃ | ≥2.3 | ≥0.8 | ||

| 3 | Elongation at Break (%) | Room Temperature | ≥450 | ≥400 |

| -20℃ | ≥200 | ≥200 | ||

| 4 | Tear Strength (kN/m) | ≥25 | ≥18 | |

| 5 | Water Tightness 30 minutes no leakage | 0.3Mpa | 0.3Mpa | |

| 6 | Low Temperature Bending | -40℃ | -30℃ | |

| 7 | Heating Shrinkag | Extend | ≤2 | ≤2 |

| Shrink | ≤4 | ≤4 | ||

| 8 | Hot Air Aging (80℃*168H) | Tensile Strength Retention At Fracture(%) | ≥80 | ≥90 |

| Elongation At Break Retention Rate (%) | ≥70 | ≥70 | ||

| 9 | Alkali Resistance {Saturated Ca(OH)₂ Solution * 168H At Room Temp.} | Tensile Strength Retention At Fracture(%) | ≥80 | ≥80 |

| Elongation At Break Retention Rate (%) | ≥80 | ≥90 | ||

| 10 | Ozone Aging (40℃*168H) | Elongation 40% 500ppm | No Crack | No Crack |

| 11 | Artificial Weathering Aging | Tensile Strength Retention At Fracture(%) | ≥80 | ≥70 |

| Elongation At Break Retention Rate (%) | ≥70 | ≥70 | ||

| 12 | Bonding Peel Strength (shhet and sheet) | N/mm | ≥1.5 | ≥1.5 |

| Retention Rate of Flooding (168H At Room Temp.) | ≥70% | ≥70% | ||

Remark:

Width of ML1 = 1.2m,20m/roll,30kg/roll;

Width of MF1 = 2.0m,20m/roll,50kg/roll